How the Smart Building Gateway helps gather Meaningful Data into INVICARA Platform Solutions

Solution Specialist

Smart buildings are called so because they have the potential to provide users with in-depth data so they can take actions to increase the lifespan of the building, improve tenant comfort and reduce running costs, among other benefits.

A challenge we now face is the vast array of different data points, being collected by separate devices that cannot relate to each other, leaving the user in a grey area when it comes to interpreting the data. This is where a Smart Building Gateway (SBG) comes into play.

The objective of this post is to provide an overview of the SBG. It will explain, how it integrates with systems such as Building Management System, Metering System, Unitary controls, internet of Things (IoT) sensors, etc. It will provide an overview of how to, effectively tag a data model, and it will summarise the intelligent rules that help users at all levels to manage their immediate or long-term Smart Building goals.

Current Challenges with Collecting Building Data

In today’s world, buildings are managed by different controls or systems in a siloed approach, each with their own proprietary software tools. There is little to no exchange of data across them which limits the opportunities for optimised building operations. The data defined by each system/software are not meaningful enough to be understood by other systems/software. Let’s see how the SBG helps to address the above challenges.

What is the Smart Building Gateway (SBG)

The SBG was designed to integrate with disparate IoT systems and provide immediate access to data so that it can be viewed, manipulated and stored easily.

It is a fanless Linux PC and looks like a hub switch, which is supplied to each site. It is pre-loaded with necessary software tools and VPN set up. On receipt of this unit at the site, it auto connects to Twinit.io’s Performance Twin.

How easy is it to setup SBG at Building site?

The user just needs to power up to local AC source and connect BMS/Controls LAN and internet to different ports or to the same port based on the IT policy. At the building site, no expert is needed, there is nothing to set up, plug in the power and it ports in a few minutes, secured connectivity makes it simple and Ready-to-Connect instantly.

Does the Technical Team need to visit each Site for Configuring SBG?

No. Once the SBG is hooked up to the cloud, all project setup activities are carried out remotely. Support is needed by from the client only during escalations only if specific challenges arise at the site.

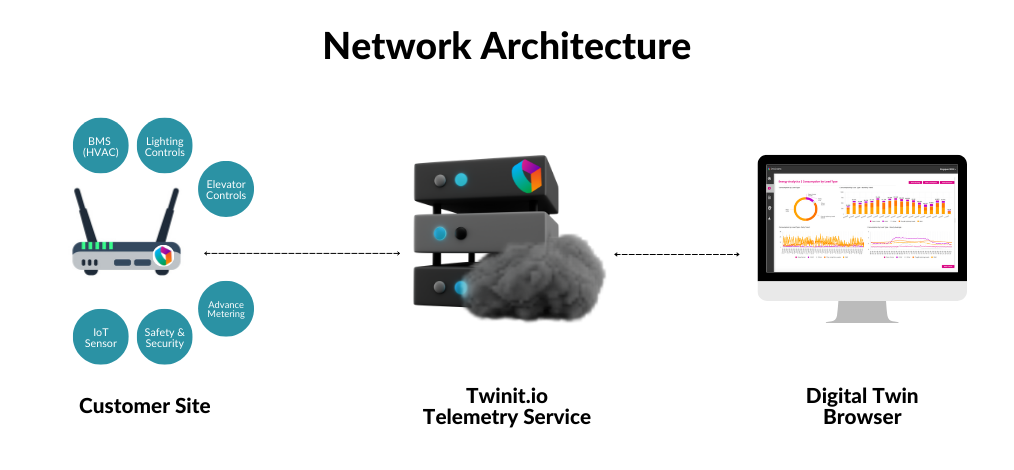

How Does Data Flow from the SBG?

Refer to the network architecture schematic shown below.

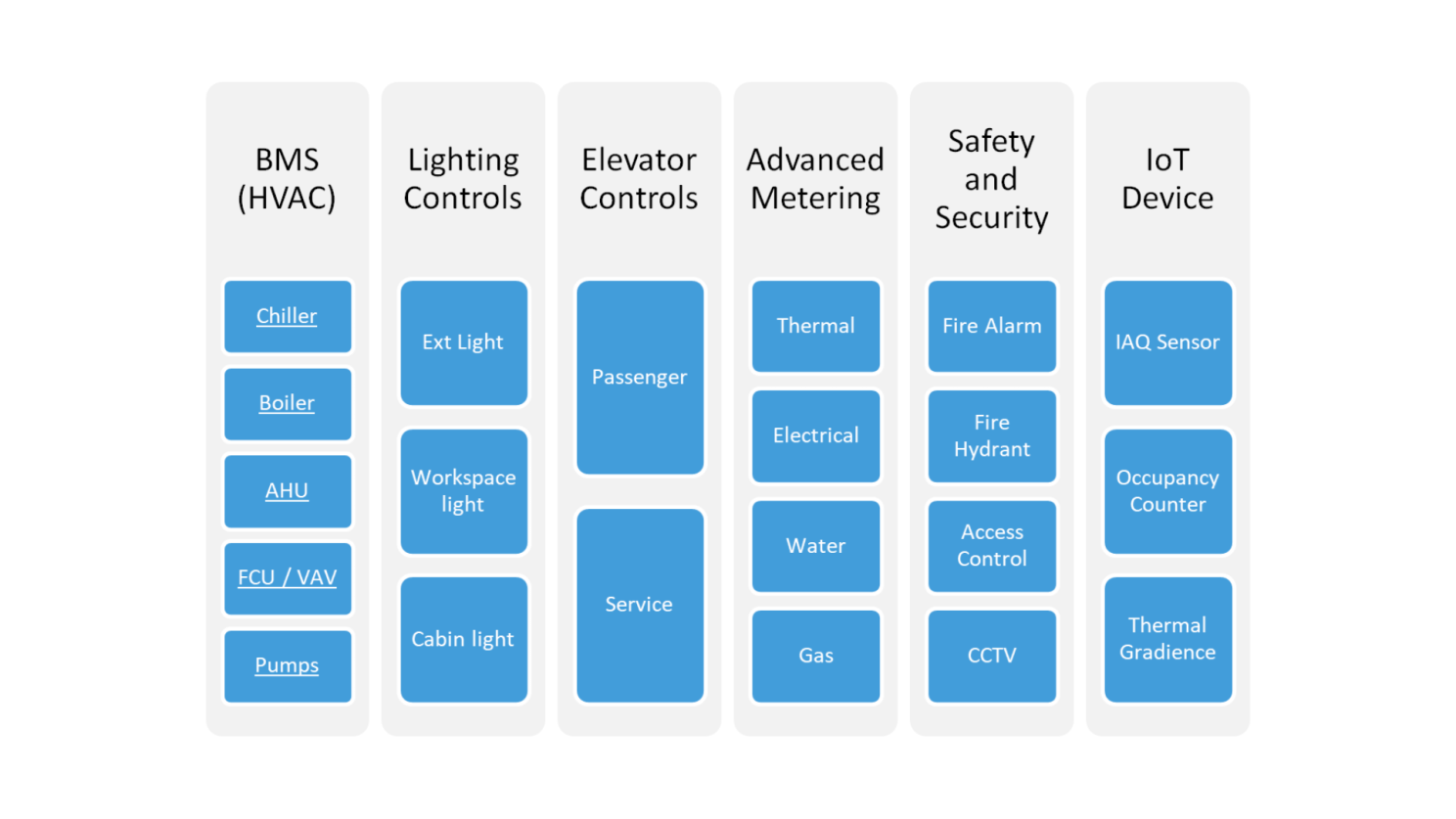

Does the SBG only Integrate with BMS?

No, it extends to any communicable devices (Plant Controls, Metering devices, IoT devices, Fire Alarm systems, etc.) preferably with standard open protocols.

Devices that are not hooked with the BMS but are available on the network could also be integrated with SBG.

In some cases, the client is a tenant and does not have any access to building controls. In these specific cases, where the clients just wants to install various wireless sensors (IAQ, True Occupancy, Temperature gradience), they can seamlessly integrate these systems with the SBG via IoT protocols.

Devices that support proprietary protocols can be integrated with SBG using cost effective 3rd party bridge solutions so they are not left out.

Are there any Prerequisites for the SBG before Deployment to Site?

Yes. There is a simple checklist for the client or the product supplier for basic confirmation and simple validation at site using 3rd party free tools. These checklists ensure there are no surprises at a later date.

Also based on client input, we can define a data model for the equipment, metering etc., and get clear focus on those rather than focusing on entire data set.

As the project expands, the data model would be modified accordingly and the SBG connectivity extended to those as well, providing more flexibility.

Supported Protocols & Interfaces by the SBG

- BACnet

- Project Haystack

- Microsoft SQL Server

- SNMP

- OPC UA

- Modbus

- {REST}

- MQTT

- Energy Star Portfolio Manager

- oBIX

- Sedona

How to Decode a Large Set of Building Data planned in SBG?

Decoding of the large datasets produced by buildings is done in a phased approach.

- Based on Client O&M document a, high level network architecture is defined.

- Further devices are discovered live or mapped in the SBG.

- The data points in the hierarchy can then be defined. For example, Building – floor – space – equipment – Datapoint.

- Adding to this, the relationships between equipment are also captured. For example, AHU1 serves VAV1-10 also captured. Further AHU1 is powered by Feeder 1 has energy meter EM1.

This defines the data model of the building controls and is used to isolate specific devices which have a fault, resulting in huge time and cost savings.

The above is the basis of the building taxonomy or ontology, which provides the client with a standardised approach to mapping their data and data requirements, which in turns helps them to manage buildings across their portfolio independent of the underlining product and make being used.

What is Tagging in the SBG and how it is used?

Today’s automated smart buildings need standardised semantic metadata (tagging) for the entire set of building data collected or going to be collected. This might be called as standard library across the portfolio. Tagging is like inserting multiple feathers to understand “who am I”, differentiate from others “uniqueness”, category “group I belong to”, value definition “proper Units”, etc.

With proper tagging, analytics applications in SBG can quickly consume data from equipment systems and interpret patterns in operational data to identify faults, deviations, and trends that can be addressed to improve efficiency and insure proper operation of equipment systems.

Does the SBG provide Live Data and how is the Data Stored?

Yes, the user can see live data for operational purposes. The data is stored inside the SBG, this combines the speed of industrial historian with the modelling capabilities of document and graph databases to store and organize heterogeneous data.

This data is replicated in the cloud as well for data redundancy. Historian uses advanced compression to efficiently store billions of time-series records in a fraction of the disk.

The real-time varying analogue data is stored at 15 min intervals. Digital data and setpoint data are stored during change of value.

Conclusion

Hope the above content helps to understand the need of SBG and how it spreads over in building network to sniff and connect to building devices using inbuilt connector with wide coverage of wired and wireless building / IoT protocols.

The connected device data are properly tagged for its accurate representation and stored efficiently within SBG for power full views, analysis and diagnostics that helps user to take decision faster.

There is no doubt by following these process would make every building move towards smarter and high performance buildings meeting current and future competitive needs.

If you want to learn more about how Smart Building Gateway can help in your situation, contact us here: https://invicara.com/about#con...